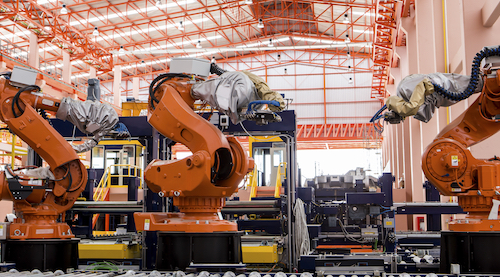

Industries Served: AUTOMOTIVE INDUSTRY

Material Handling:

CSD can provide solutions including robotics, gantries, pick and place systems along with an array of conveyor solutions to automate your material handling needs.

CSD can provide solutions including robotics, gantries, pick and place systems along with an array of conveyor solutions to automate your material handling needs.

Contract Engineering:

Providing engineering services to upgrade existing control systems, migrate networks, and implement data collection and reporting are a few of the key services provided by CSD.

Providing engineering services to upgrade existing control systems, migrate networks, and implement data collection and reporting are a few of the key services provided by CSD.

Integration Services:

Having both mechanical and electrical engineering under one roof allows us to provide an array of integration solutions to upgrade or install new automation in your facility.

Having both mechanical and electrical engineering under one roof allows us to provide an array of integration solutions to upgrade or install new automation in your facility.

Our Industries Served: PROJECT EXAMPLES:

A Tier 1 Automotive supplier was in the middle of a plant wide upgrade and an existing control was accidentally removed and gutted. All wiring was cut out and the hardware was removed from the back panels and slighted for scrap. CSD received a call on a Monday morning asking if we could rebuild this 3 door, 72 inch tall control panel. We scramble our team and worked extended shifts to support our client. The crucial part of the rebuild was they needed it by that Friday and they got it by Friday.

An automotive structural frame manufacturer had an existing production line using AB DeviceNet to network the entire system. The network had reached its maximum capacity and they needed to modify the line and add more nodes. The decision was made to upgrade the PLC and split the main trunk line into two different networks. CSD engineered the changes and implemented the new network over a three day holiday weekend, working around the clock with teams alternating shifts. This enabled the complete system upgrade to be completed without impacting production.

Industries Served: CONSUMER PRODUCTS INDUSTRY

Material Handling:

Providing complete packing lines and product transfer for products, case goods, and palletized goods using CSD equipment and other packaging and material handling OEM equipment.

Providing complete packing lines and product transfer for products, case goods, and palletized goods using CSD equipment and other packaging and material handling OEM equipment.

Industries Served : Contract Engineering

We engineer solutions for track – trace – control, automation upgrades, batch and recipe management, facilities layout and design CSD, and complete MES solutions.

We engineer solutions for track – trace – control, automation upgrades, batch and recipe management, facilities layout and design CSD, and complete MES solutions.

Integration Services:

Creating manufacturing lines that act as a single unit from various OEM manufactures is a unique specialty for CSD, implementing supervisory control systems and reporting are only a part of our service suite.

Creating manufacturing lines that act as a single unit from various OEM manufactures is a unique specialty for CSD, implementing supervisory control systems and reporting are only a part of our service suite.

Our Industries Served: PROJECT EXAMPLES:

An international paint manufacturer needed to perform a plant expansion to add capacity. A major portion of the expansion was a complete 5 gallon packaging line. CSD was contracted to complete the design, fabrication, equipment sourcing, and installation to provide a turn-key packaging line. All aspects of the project were managed by CSD. Due to location and cost CSD contracted local skill trades to perform the installation phases. By subcontracting this portion of the project we were able to reduce the client’s overall investment. Our experienced project management team was able to orchestrate the installation and commissioning of the line by effectively pulling all resources and schedules together into a cohesive team. The project was completed on schedule and within budget. Since completing the line CSD has continued to expand its services with this client.

A major pet foods manufacturer has been a long term regional contract engineering services client since 2003. CSD has completed a broad array of services for this client ranging from facilities documentation, packing line upgrades, OEM FAT, energy studies, safety upgrades, data collection, custom software development and reporting. By utilizing CSD in this manner we have become a true partner for them and a virtual extension of their engineering team. What this client has found is they benefit in multiple ways by standardizing their contract engineering services to complete projects. We have now expanded our support to three additional locations across the country and continue to expand our range of services we provide for them.

Industries Served: FOOD AND BEVERAGE INDUSTRY

Material Handling:

From raw materials to palletized case goods CSD is developing solutions encompassing fillers, labelers, case packers, case sealers, palletizers, and stretch wrappers along with all of the transfer equipment in between.

From raw materials to palletized case goods CSD is developing solutions encompassing fillers, labelers, case packers, case sealers, palletizers, and stretch wrappers along with all of the transfer equipment in between.

Contract Engineering:

We engineer solutions for track – trace – control, automation upgrades, batch and recipe management, facilities layout and design CSD, and complete MES solutions.

We engineer solutions for track – trace – control, automation upgrades, batch and recipe management, facilities layout and design CSD, and complete MES solutions.

Integration Services:

Processing dry goods and liquids from raw the materials to processing, transfer, and packaging is a core capability for CSD, our mechanical and electrical teams work cohesively to provide turnkey integrated solutions.

Processing dry goods and liquids from raw the materials to processing, transfer, and packaging is a core capability for CSD, our mechanical and electrical teams work cohesively to provide turnkey integrated solutions.

Our Industries Served: PROJECT EXAMPLES:

A US based contract bottling firm needed to install a new Vodka bottling line. CSD was contracted to complete a turn-key solution. We engineered the complete packaging line from incoming cases of empty glass to palletized and stretch wrapped pallets of finished goods ready for shipment. CSD project managed all aspects of the project including sourcing of key equipment from OEM’s to the integration of a complete Ethernet/IP backbone to monitor and control bottling Line. The overall system utilized a variety of brands and models of PLC’s and HMI’s. The complete line included a Case Dumper, Bottle Washer, Filler, Capper, Labeler, Laner, Case Packer, and Case Sealer. CSD engineered the complete controls solution to tie all equipment together to operate as an engineered solution rather than independent pieces of equipment. The line was installed and commissioned on time and within budget.

A packaged food manufacturer had multiple lines that were networked using DeviceNet. Due to the inherent difficulty with DeviceNet and troubleshooting problems the customer elected to upgrade their entire facility to Ethernet/IP. CSD developed a plan and implemented a plant wide network upgrade. Each processing system was individually evaluated and targeted based on need and downtime. We then systematically upgraded the lines to mitigate downtime and improve overall efficiency.